A game changer

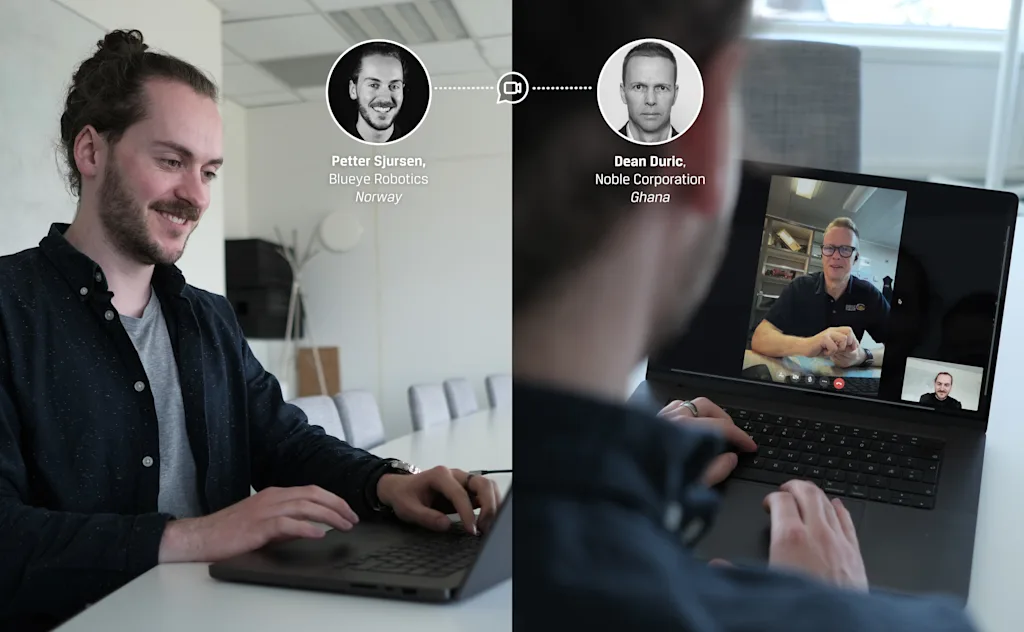

Following their merger with Maersk Drilling in 2022, Noble integrated the Blueye X3 mini-ROV into their inspection toolbox. The result has been a significant reduction in inspection times, costs, and risks. We called up Dean Duric, Marine Section Leader and Barge Engineer at Noble Corporation. Dean is a Master Mariner with over 15 years of experience gained on board various sizes and types of ships. In the videocall he shared his insights on their experience with the X3.

The primary use of the Blueye X3 at Noble has been for ballast tank inspections, where they once inspected 19 ballast tanks in just two days! Duric recounted a recent operation:

I have used it extensively over the past week or so. We inspected tanks that were 90-95% full, navigating through many compartments, frames, and openings. Initially, it was time-consuming, but with better planning, we significantly reduced the time needed. We have completed many ballast tank inspections, saving over 150 man-hours, likely more!

- Dean Duric, Marine Section Leader, Noble Corporation.

Better overview than traditional divers

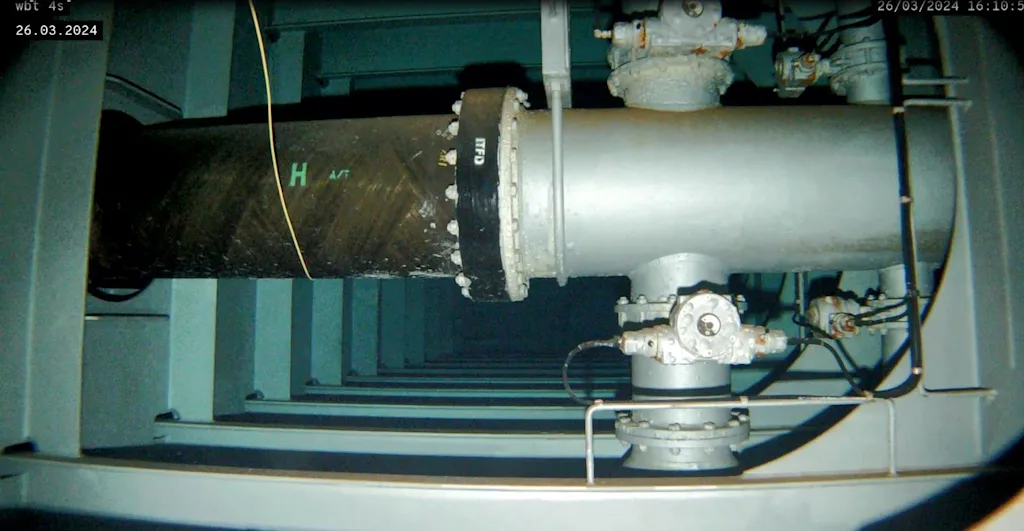

The high-quality video output from the drone also impressed Duric, who noted that the visual clarity provided a better overview than traditional diver inspections. The improved visual data helps the team to do more thorough inspections and make smarter maintenance choices.

I was surprised with the quality of the drone videos. It’s really, really good quality, and I must say that in some areas when I'm inspecting the tanks I have better overview than when I'm doing the in-tank physical inspection as a diver.

- Dean Duric, Marine Section Leader, Noble Corporation.

The importance of ballast tank inspections

Ballast tanks are crucial for keeping ships, including Noble Corporation’s drill ships, stable and structurally sound. Regular inspections are key to preventing corrosion and structural issues that could jeopardize the vessel’s safety and lower its value. Traditionally, this meant sending in divers or emptying the tanks, both of which are risky and expensive.

Skipping these inspections can lead to big problems, like structural failures and costly repairs. Plus, the confined and dangerous environment of ballast tanks puts divers at serious risk. That’s why finding safer, more efficient ways to inspect these tanks is so important.

There are definitely huge risks of using divers, especially if you're looking at how much the guys, including myself, are exposed when we enter the tanks. I would say there is no price, there is no large enough amount, that you would make up for the risk.

- Dean Duric, Marine Section Leader, Noble Corporation.

Crucial thruster Inspections in Ghana – Saving up towards $200 000

Noble Corporation also utilized the Blueye X3 for a critical thruster inspection on a drill ship in Ghana, June last year. The team suspected fishing nets entangled in the aft thruster. Duric shared the success story: “Using the mini-ROV, we confirmed the thruster was clear, saving significant rig operational time and money.” The alternative would have been waiting for a dive team and stopping the drilling operation, costing up toward $ 200 000.

Noble recently purchased the new Blueye High-Capacity Battery, to increase their drone’s operational time. The battery was launched towards the end of 2023, and more than doubles your dive time. Dean mentioned; “I use the new high-capacity battery extensively, in all tank dives. With this battery, I can now probably do three tanks in one go - Easily. It works really well within the ballast tank.”

Blueye Academy Training in Norway

To maximize the benefits of the Blueye system, Noble sent four team members to our office in Norway, for the Blueye Academy training program. The training covered the technical basics, underwater task solutions, data processing, and maintenance. Duric praised the training program, saying;

I found it very good, with a lot of practical information. It has helped us perform our tasks effectively. I highly recommend the training for anyone operating the unit.

- Dean Duric, Marine Section Leader, Noble Corporation.

"Not a toy"

When asked why not more companies are following Noble’s lead with drones for tank inspections, Dean reflected on how he thinks many people might not understand the full capabilities of the Blueye ROV and what it can handle.He suspects that people still compare it to flying drones, “Those flying drones that costs $600 or so, and are capable of doing nothing. Which I would say they're completely wrong. The Blueye drone is not a toy."

If it was up to me, if I had the power, I would definitely use Blueye ROVs instead of divers, to eliminate the risks. I would have one on all vessels.

- Dean Duric, Marine Section Leader, Noble Corporation.

Noble's use of the Blueye X3 mini-ROV is a big step forward in offshore drilling. By boosting safety, cutting costs, and making inspections more efficient, Noble is setting new industry standards. The success stories from their ballast tank and thruster inspections show just how game-changing this tech can be for traditional maintenance.